A Purdue University initiative is tackling a critical economic challenge: helping small and midsize manufacturers adopt digital technologies to improve efficiency and remain competitive. The innovative engagement model, ManuFuture Today, developed with support from the National Science Foundation (NSF), has shown promising results, including one success story where a participating company more than doubled its productivity within a year.

ManuFuture Today addresses a long-standing issue for small and midsize manufacturers, which make up 98.6% of all U.S. manufacturing firms and employ nearly half of the industry’s workforce. Despite their importance, these firms often lack the resources—time, funding, and expertise—to leverage the transformative potential of digital technologies.

Ali Shakouri, a professor in Purdue’s Elmore Family School of Electrical and Computer Engineering and Associate Dean for Research and Innovation for the university’s College of Engineering, is leading the effort.

“ManuFuture Today is not just about isolated success stories,” said Shakouri. “It’s about establishing a replicable engagement model that empowers small manufacturers to navigate their digital transformation through collaboration and peer learning.”

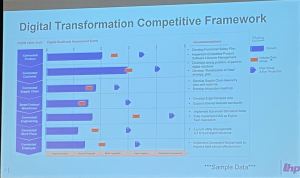

The ManuFuture Today methodology centers on forming learning and innovation networks—cohorts of manufacturers focused on specific challenges—guided by Purdue researchers and industry experts. Manufacturers meet regularly with researchers. Every six months, stakeholders convene to share progress, exchange knowledge, and explore new strategies for overcoming barriers to technology adoption.

The challenges of small and medium manufacturers seem far from cutting-edge research in universities and big companies pushing the limits of artificial intelligence and new manufacturing processes. Researchers from several schools in the Colleges of Engineering, Science, and Polytechnic at Purdue, in collaboration with partners at Harvard, Tuskegee University, and Ivy Tech Community College, have identified important research opportunities in developing privacy-preserving artificial intelligence data communities1 as well as reliable sensing with low-cost internet-of-thing and tiny machine learning devices.

Rather than imposing top-down solutions, the program emphasizes helping manufacturers design their own digital journeys. Technological innovation must be coupled with organizational culture and business operation changes where front-line workers take ownership. Manufacturing cohorts take the lead in implementing and customizing solutions, engaging their workers and fostering sustainable innovation.

“We don’t simply hand them Purdue technology and expect magic to happen,” Brad Beach, Managing Director for ManuFuture, said. “We engage them in a process of learning by doing, and along the way they learn how to evaluate the impact of sensors and data, how to think about and apply AI models, how to integrate commercial solutions, how to apply their own in-house innovations, and most importantly, how to add real value to their business.”

One standout success involves Kirby Risk Precision Machining (KRPM), a supplier to industries including agriculture, oil and gas, and power generation. KRPM faced inefficiencies stemming from limited visibility into shop floor operations and reliance on manual production reports.

Through its involvement in ManuFuture Today, KRPM collaborated with Purdue researchers to deploy low-cost sensors, data analytics, and intuitive dashboards. The initial results were very encouraging. Subsequently, KRPM identified a commercial vendor to connect all of their tools digitally. As data and information flow were overwhelming, they developed a custom communication flow and data interface with open-source tools with the help of a Purdue intern. The results were transformational: in just one year, KRPM doubled its productivity.

“Before this transformation, communication relied on handwritten notes and in-person conversations,” said KRPM Continuous Improvement Manager Dave Roberts. “Operators would walk an average of 62 miles annually to locate supervisors, costing 370 hours of productivity.”

With the new system, operators now use tablet-based dashboards to monitor machine performance and request support instantly. These innovations eliminated inefficiencies and streamlined workflows.

Beyond internal improvements, KRPM has become a role model for other manufacturers in the cohort, sharing its journey and lessons learned to inspire broader adoption of digital solutions.

ManuFuture stakeholder meeting on Dec. 9, 2024 on the West Lafayette, IN, campus of Purdue University

In another example, Primient, a food processing company in Lafayette, has been working with Purdue and Harvard to implement a simple machine learning imaging application to help its operators evaluate its production process for the size distribution of sugar crystals2. The new application provides measurement precision to a process previously prone to human error and wide variability. The tool has been used daily for over a year by more than 30 operators.

The ManuFuture Today initiative has drawn national and regional attention, which was highlighted in an article in Harvard Business Review. Several dozen manufacturers in Indiana and Northeast Ohio currently participate in the multiple learning and innovation cohorts. The program’s success highlights the potential of combining artificial intelligence with peer learning to accelerate digital transformation.

“We’ve proven this engagement model works at a regional level, but the challenge now is scaling it nationally,” Shakouri said. Purdue is now working with regional, state and national partners to expand ManuFuture Today’s reach.

As the manufacturing industry faces growing pressure to modernize, ManuFuture Today offers a scalable and sustainable solution to help small and midsize manufacturers adapt and help create a more resilient US manufacturing ecosystem. By fostering collaboration, building trust, and focusing on achievable outcomes, the initiative is driving real change and strengthening the backbone of the U.S. economy.

“Small wins lead to big transformations,” Beach said. “ManuFuture Today is proving that, with the right support, even the smallest manufacturers can achieve extraordinary results.”

1Beyrle Barker L, Shank J, Sweeney L. “Trustworthy AI Data Communities (AI-DCs): Unlocking the benefits of AI for all, using U.S. manufacturing as a case study.” Accepted for publication in the Journal of Technology Science, Jan. 2025

2Ji X, Shorland J, Shank J, Delpe-Brice P, Sweeney L, Allebach J, Shakouri A. “Empowering Manufacturers with Privacy-Preserving AI Tools: A Case Study in Automating Quality Control Through Machine Learning.” Submitted to publication in ACM Queue, Dec. 2024